Harold Hardy is his name. We can all remember his name. He, on the other hand... The classic Harold Hardy hail is waving his finger at somebody, saying "Hey, aaaaah..." His default name for anybody is "Number One." At first, co-workers are put off by his apparent disinterest in learning their names. I know I was. The turning point for me was when I worked with Harold and his son, Harold Hardy Junior, at the same time. Harold. would address his own son, who had the same name, given to him by him, waving his finger saying "Hey, aaaaah... Number One!"

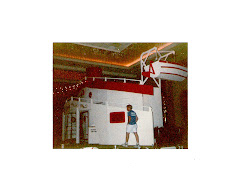

I first worked with Harold Senior at the Star Wars installation. Mystic sent in the big guns for a lot of days and nights. Harold was 'Router Man,' when things didn't exactly fit right when the glass cases went together. He is a genius at seeing how a router with a top bearing bit and a stick to run the bearing on can solve any problem. I was in awe. Over the four years we worked on many projects together, and became buddies. Our musical tastes had many overlaps, most notably George Benson and Earth Wind & Fire. I kept his projects better organized "Where's the paper for this cabinet?" he'd ask. I'd rescue it from whatever precarious willy nilly place he'd forgotten and left it - on the floor somewhere or on the saw table or the lunch table - wherever. I used to demonstrate the Harold Hardy method of organization: I'd take the armload of drawings and specifications and just fling them into the air so they landed everywhere. Then I'd pick them up and keep them safe and together.

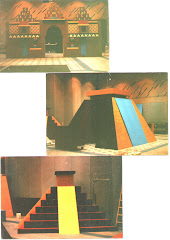

Our first real collaboration was the New England Sports Network set. We were filling a whole studio with columns, flats, decks, curved steps, frames with fabric stretched across, and a lot of laminate. I had ten years of F/X experience building television news sets, so I was actually more at home than Harold was with this particular kind of construction. By the time we were ready to install it, he was as impressed with my work as I was with his.

If you let him, he'll suck you dry of pencils and cigarettes. You can foil the pencil 'borrowing' by carrying flat carpenter pencils - he doesn't like those. The only way to stem the flow of cigarettes is to run out, or just refuse to give him one. I couldn't do that. I really liked the guy.

I haven't heard anything about Harold since I left Mystic over two years ago. I hope he's still doing well.

Monday, August 22, 2011

Sunday, July 10, 2011

The Opening Was Just The Beginning

Mere days after the opening of the Star Wars exhibit, we were back in the Museum Of Science early on Saturday morning, October 29th. The "Air Car" ride was malfunctioning. Armed with drills and hammers and implements of destruction, we tore apart the little enclosed track and put it back together with a stronger knee wall around it. The broken plate on the car itself, a swivel thing that allowed steering, was removed so it could be returned to the shop for repair or replacement. A sign was placed at the entrance to the ride: "The Repair Droids are still working on this activity. Please come back later." Six months later, when disassembling and packing the exhibit for its world tour, I happened upon that sign. I still have it.

November, December and January I was often derailed from my Norwood projects for night shift gigs at MOS. Broken things were replaced and newly acquired elements were added that there hadn't been time for before opening. Cabinet doors were added, venting holes and fans were installed, labeling signs were installed on permanent posts, all kinds of little things.

And then we began a systematic measuring of all thirty-some glass cases, complete with drawings of the power inlets and forklifting access panels. Why? Because crates were required for shipping these giant glass boxes. Kevin and I spent several nights taking careful measurements. He wrote down the numbers and drew the locations of whatever needed to be accomodated. We compiled the "bible" of Star Wars crates and then began to assemble sides back at the shop. These were not your usual crates. They were individual sides, with 2X2 around the edges, drilled for bolt assembly. The top was a 1X6, mitred on the ends, that hooked over the top of the case. A huge stack of these sides began piling up in the shop, until Kevin took a bunch to the Museum to begin test-fitting them and modifying whatever slight miscalculations there might have been. For a couple of weeks, I was crate building guru, while Kevin worked nights fitting and tweaking.

May Day! May Day! Monday, May first was the beginning of the strike. I, of course, was put on the strike crew. I hardly did any striking, however. I was put on the finishing up project. There was a long list of trim pieces to add, threaded inserts to install, sign holders to secure for transport, and securing anything loose. Two weeks we spent finishing as many details as possible, packing things up and loading them onto thirteen semi trailers. That's a lot of stuff.

Star Wars has been all over the country and all over the world - Alaska, Europe, Japan, Australia, New Zealand, and on and on. Shawn Marler and Vinnie Canney have been the point men from Mystic taking turns unloading, unpacking and setting up - and striking, packing and loading. I suppose that, five years later, it's still on tour. I hope it's finally finished by now.

November, December and January I was often derailed from my Norwood projects for night shift gigs at MOS. Broken things were replaced and newly acquired elements were added that there hadn't been time for before opening. Cabinet doors were added, venting holes and fans were installed, labeling signs were installed on permanent posts, all kinds of little things.

And then we began a systematic measuring of all thirty-some glass cases, complete with drawings of the power inlets and forklifting access panels. Why? Because crates were required for shipping these giant glass boxes. Kevin and I spent several nights taking careful measurements. He wrote down the numbers and drew the locations of whatever needed to be accomodated. We compiled the "bible" of Star Wars crates and then began to assemble sides back at the shop. These were not your usual crates. They were individual sides, with 2X2 around the edges, drilled for bolt assembly. The top was a 1X6, mitred on the ends, that hooked over the top of the case. A huge stack of these sides began piling up in the shop, until Kevin took a bunch to the Museum to begin test-fitting them and modifying whatever slight miscalculations there might have been. For a couple of weeks, I was crate building guru, while Kevin worked nights fitting and tweaking.

May Day! May Day! Monday, May first was the beginning of the strike. I, of course, was put on the strike crew. I hardly did any striking, however. I was put on the finishing up project. There was a long list of trim pieces to add, threaded inserts to install, sign holders to secure for transport, and securing anything loose. Two weeks we spent finishing as many details as possible, packing things up and loading them onto thirteen semi trailers. That's a lot of stuff.

Star Wars has been all over the country and all over the world - Alaska, Europe, Japan, Australia, New Zealand, and on and on. Shawn Marler and Vinnie Canney have been the point men from Mystic taking turns unloading, unpacking and setting up - and striking, packing and loading. I suppose that, five years later, it's still on tour. I hope it's finally finished by now.

Friday, July 1, 2011

Luke!....Luke!

Years ago, and I'm talking decades ago - say, 1988 or '89 - I was in the Orlando Science Center when a big section was walled off. Througfh cracks in the temporary walls I could see crews working, installing exhibits. "Wow!" I said. "I could do that job!"

Flow downstream to 2004. We were in Boston for Carmen's thesis presentation in April, and her graduation from Lesley University in May. It seemed like every place we went we went within view of the Museum of Science. I gazed hungrily at it. I wanted to go there.

Another year and four months passes, and I'm called into the office, issued my first "Mystic Scenic Studios" T-shirt and told to show up with my tools the next morning at 7:00 at the Museum of Science to work for a few days. Double you oh double you.

The next morning was my first experience with the MBTA's "bus replacement" service. One of the effects of the Big Dig was that it interrupted service on the Green Line west of North Station - where Science Park station is located - so there was "bus replacement" service to get people there. Knowing what I know now, I would have skipped the Green Line altogether, but I didn't. Since my intention was to get there forty five minutes early, even with the hellacious cluster fuckage that is MBTA "bus replacement" service, I was fifteen minutes early. Which means I beat Kevin Simard, the Mystic crew boss, by about forty five minutes.

From information gleaned then and since, I believe I understand the situation. First of all, the Museum Of Science (MOS) contract was administered by Allan McNab, not Jim Ray or Jon Hondorp, which means that Kevin got for his crew whoever those two company owners were willing to let go. The dregs, for the most part. So Kevin and the dregs had been in there for quite a while building walls and rooms and other assorted structures for the new "Weather" exhibit in the big room where the World's Largest Air Insulated Vandegraff Generator works its lightning magic two shows a day. They needed expert help to finish up. Most of the really good carpenters at Mystic live south, in or near Norwood and Dedham. They hate to drive into the city. I, on the other hand, lived in Belmont, and the MOS was closer for me by far.

They needed to finish up because pieces of the brand new Star Wars exhibit were on trucks rolling out of Norwood a couple times a week. This meant stopping work on the Weather stuff, cleaning up and securing everything, going out to the parking garage, unloading a huge chunk of the Millennium Falcon, rolling it on dollies to the storage room, and then going back to work on Weather.

I didn't much like Kevin. He was a crack head, a smart-ass and a practical joker, but he had a long-standing rapport with the Museum people. He had been the Mystic Man there for eight years, and knew every inch of the building and every quirk of the Exhibits Department personnel. I loved working at the Museum, even if it meant working with Kevin. Kevin liked me because a) I could get things done and done right, and b) I have no authority issues. He told me what to do and I said "Yes sir!" and did it.

Too soon I was called back to Norwood for some Jim Ray job or Jon Hondorp job that needed all competent hands.

The next time I went back to MOS was for the Star Wars Exhibit installation. This was either at the end of September or the beginning of October. It turned out that what Mystic was sending to be installed wasn't anywhere near finished. All of the big glass cases were a base, a back board, a ceiling and three or four or five or six sheets of tempered glass, half an inch thick. Oh yes, and many cases of clear adhesive caulk. A base was positioned and leveled, a ladder was placed on it, and the back board was glued and screwed to the base. Caulk was squeezed into the groove near the edge, and a sheet of glass, maybe three feet wide by seven feet tall, was dropped into the groove. A person sat on the ladder and held the glass while caulk was squeezed for the next sheet of glass, and the next. The last sheet of glass was the door, no caulk allowed. Then the ceiling piece had its grooves caulked, except for the side where the door was, and it was hoisted up to guys on ladders who handed it over to the inside person, and it was eased down, glass being teased into grooves and the back board screwed into place. The door was removed so that the inside person could escape the caulk fumes and the precision caulking crew could connect the corners and other seams while the base levelers moved on to the next case.

There were about thirty TV panels, where a monitor was fitted into a pre-cut rectangular hole, a graphic panel was fitted over it, and holes needed to be drilled for control buttons for "UP" "SELECT" and "DOWN." This was my introduction to drilling one inch holes through quarter inch plexiglass with a paddle bit. Before Kevin showed me how, I would have sworn that it couldn't work. It works! So job one was to figure out which TV panel you had going, and match it up with its corresponding graphic mounted on the back of oversized quarter inch plexiglass, place it exactly where the monitor was masked perfectly by the opening in the graphic, and mark the graphic exactly where it needed to be cut. Out in the outer room where the gift shop would be, there was a work table set up. You placed your quarter inch plexiglass with the graphic mounted on it, set a straight edge along the cut marks, and ran your router along the straight edge. Then you took your resized graphic panel back to the TV panel, clamped it in place, and began drilling holes for screws and 'finish washers' around the perimeter. Once the graphic was attached, you marked your control button locations and began to slowly drill your one inch holes through the plexi, through the graphic and through the board of the TV panel. Then clean up the mess, install the buttons and move on. About ten of the thirty were instances in which the graphic didn't match the location of the monitor via miscommunication between the designer, Allan McNab, the carpenter(s) or the graphics company. Usually it meant ordering a corrected graphic panel (about $700 each) but a couple of times I was modifying monitor openings to accomodate the graphic. This all took many days. Between the TV panels and all the other exhibits that required control buttons, I estimate that I drilled about five hundred of those one inch holes through plexiglass. It was noisy, too. Throughout the gallery people were complaining about the "screeeyaareeyaareeyaa" noise my paddle bit made, hole after hole, for days on end.

Sixteen hour days were the norm for about two weeks, starting at 6:00am and working until 10:00pm. More and more heavyweight carpenters arrived as opening day drew closer. We started having an overnight shift in addition to the day shift. Tireder and tireder we got. One memorable night at about 7:30, Allan McNab took me over to a panel with about sixteen posts sticking up. He showed me the graphic that was supposed to fit over the panel, with the posts sticking up through it. My job, in my exhausted state, was to drill holes in the plexiglass

graphic so that the posts would stick up through it. I unscrewed posts while Allan looked for a big enough (16" X 30"?) sheet of paper to do a rubbing. I checked the graphic to see if it was the exact right size, and it was. I taped the paper over the panel and rubbed with a pencil over the sixteen or so holes. Then I taped the paper to the plexiglass and, using a plexi drill bit, drilled my holes. Only one gave me trouble, because the post screwed into the unit at a slight, maybe 5 degree angle, so the hole needed to be enlarged and angled correctly. When all was said and done, if you went looking for imperfections, you could see that slightly skewed hole. Otherwise, you'd never notice it. It looked good, and no one was more surprised than I.

One by one the looping narrations were turned on and allowed to run all day and all night, to test their durability. There was a face recognition exhibit that had a forlorn voice that periodically called out for someone to come over for a face recognition lesson. Every three minutes or so, he'd say something like "Hey there, come on over." Three minutes later, "I see you." There were probably seven or eight phrases that would suddenly break the silence while we were working. And maybe once an hour, and when we heard it we weren't at all sure we'd really heard it, he'd say, "I see dead people." The Millennium Falcon model, the four foot diameter model used in the first film, had a narration about the winding-up sound effect they used when the hyper drive was malfunctioning, complete with Lando's "YeeeeHawwww" when it finally kicked in. But the lullapalooza, the one that haunts all of us to this day, was the movie clip that ran beside the landspeeder, all day all night. It started out, all day, all night, every time, with Aunt Beru yelling "Luke! Luke!" Chills!

The day before opening there was a reception for the press and whoever they could get for celebrities. George Lucas was coming. The reception was to be at 7:00, so they chased us out at 6:00. "Wow, cool, a short day!" we said. "Wait a minute, that was a twelve hour day!"

Flow downstream to 2004. We were in Boston for Carmen's thesis presentation in April, and her graduation from Lesley University in May. It seemed like every place we went we went within view of the Museum of Science. I gazed hungrily at it. I wanted to go there.

Another year and four months passes, and I'm called into the office, issued my first "Mystic Scenic Studios" T-shirt and told to show up with my tools the next morning at 7:00 at the Museum of Science to work for a few days. Double you oh double you.

The next morning was my first experience with the MBTA's "bus replacement" service. One of the effects of the Big Dig was that it interrupted service on the Green Line west of North Station - where Science Park station is located - so there was "bus replacement" service to get people there. Knowing what I know now, I would have skipped the Green Line altogether, but I didn't. Since my intention was to get there forty five minutes early, even with the hellacious cluster fuckage that is MBTA "bus replacement" service, I was fifteen minutes early. Which means I beat Kevin Simard, the Mystic crew boss, by about forty five minutes.

From information gleaned then and since, I believe I understand the situation. First of all, the Museum Of Science (MOS) contract was administered by Allan McNab, not Jim Ray or Jon Hondorp, which means that Kevin got for his crew whoever those two company owners were willing to let go. The dregs, for the most part. So Kevin and the dregs had been in there for quite a while building walls and rooms and other assorted structures for the new "Weather" exhibit in the big room where the World's Largest Air Insulated Vandegraff Generator works its lightning magic two shows a day. They needed expert help to finish up. Most of the really good carpenters at Mystic live south, in or near Norwood and Dedham. They hate to drive into the city. I, on the other hand, lived in Belmont, and the MOS was closer for me by far.

They needed to finish up because pieces of the brand new Star Wars exhibit were on trucks rolling out of Norwood a couple times a week. This meant stopping work on the Weather stuff, cleaning up and securing everything, going out to the parking garage, unloading a huge chunk of the Millennium Falcon, rolling it on dollies to the storage room, and then going back to work on Weather.

I didn't much like Kevin. He was a crack head, a smart-ass and a practical joker, but he had a long-standing rapport with the Museum people. He had been the Mystic Man there for eight years, and knew every inch of the building and every quirk of the Exhibits Department personnel. I loved working at the Museum, even if it meant working with Kevin. Kevin liked me because a) I could get things done and done right, and b) I have no authority issues. He told me what to do and I said "Yes sir!" and did it.

Too soon I was called back to Norwood for some Jim Ray job or Jon Hondorp job that needed all competent hands.

The next time I went back to MOS was for the Star Wars Exhibit installation. This was either at the end of September or the beginning of October. It turned out that what Mystic was sending to be installed wasn't anywhere near finished. All of the big glass cases were a base, a back board, a ceiling and three or four or five or six sheets of tempered glass, half an inch thick. Oh yes, and many cases of clear adhesive caulk. A base was positioned and leveled, a ladder was placed on it, and the back board was glued and screwed to the base. Caulk was squeezed into the groove near the edge, and a sheet of glass, maybe three feet wide by seven feet tall, was dropped into the groove. A person sat on the ladder and held the glass while caulk was squeezed for the next sheet of glass, and the next. The last sheet of glass was the door, no caulk allowed. Then the ceiling piece had its grooves caulked, except for the side where the door was, and it was hoisted up to guys on ladders who handed it over to the inside person, and it was eased down, glass being teased into grooves and the back board screwed into place. The door was removed so that the inside person could escape the caulk fumes and the precision caulking crew could connect the corners and other seams while the base levelers moved on to the next case.

There were about thirty TV panels, where a monitor was fitted into a pre-cut rectangular hole, a graphic panel was fitted over it, and holes needed to be drilled for control buttons for "UP" "SELECT" and "DOWN." This was my introduction to drilling one inch holes through quarter inch plexiglass with a paddle bit. Before Kevin showed me how, I would have sworn that it couldn't work. It works! So job one was to figure out which TV panel you had going, and match it up with its corresponding graphic mounted on the back of oversized quarter inch plexiglass, place it exactly where the monitor was masked perfectly by the opening in the graphic, and mark the graphic exactly where it needed to be cut. Out in the outer room where the gift shop would be, there was a work table set up. You placed your quarter inch plexiglass with the graphic mounted on it, set a straight edge along the cut marks, and ran your router along the straight edge. Then you took your resized graphic panel back to the TV panel, clamped it in place, and began drilling holes for screws and 'finish washers' around the perimeter. Once the graphic was attached, you marked your control button locations and began to slowly drill your one inch holes through the plexi, through the graphic and through the board of the TV panel. Then clean up the mess, install the buttons and move on. About ten of the thirty were instances in which the graphic didn't match the location of the monitor via miscommunication between the designer, Allan McNab, the carpenter(s) or the graphics company. Usually it meant ordering a corrected graphic panel (about $700 each) but a couple of times I was modifying monitor openings to accomodate the graphic. This all took many days. Between the TV panels and all the other exhibits that required control buttons, I estimate that I drilled about five hundred of those one inch holes through plexiglass. It was noisy, too. Throughout the gallery people were complaining about the "screeeyaareeyaareeyaa" noise my paddle bit made, hole after hole, for days on end.

Sixteen hour days were the norm for about two weeks, starting at 6:00am and working until 10:00pm. More and more heavyweight carpenters arrived as opening day drew closer. We started having an overnight shift in addition to the day shift. Tireder and tireder we got. One memorable night at about 7:30, Allan McNab took me over to a panel with about sixteen posts sticking up. He showed me the graphic that was supposed to fit over the panel, with the posts sticking up through it. My job, in my exhausted state, was to drill holes in the plexiglass

graphic so that the posts would stick up through it. I unscrewed posts while Allan looked for a big enough (16" X 30"?) sheet of paper to do a rubbing. I checked the graphic to see if it was the exact right size, and it was. I taped the paper over the panel and rubbed with a pencil over the sixteen or so holes. Then I taped the paper to the plexiglass and, using a plexi drill bit, drilled my holes. Only one gave me trouble, because the post screwed into the unit at a slight, maybe 5 degree angle, so the hole needed to be enlarged and angled correctly. When all was said and done, if you went looking for imperfections, you could see that slightly skewed hole. Otherwise, you'd never notice it. It looked good, and no one was more surprised than I.

One by one the looping narrations were turned on and allowed to run all day and all night, to test their durability. There was a face recognition exhibit that had a forlorn voice that periodically called out for someone to come over for a face recognition lesson. Every three minutes or so, he'd say something like "Hey there, come on over." Three minutes later, "I see you." There were probably seven or eight phrases that would suddenly break the silence while we were working. And maybe once an hour, and when we heard it we weren't at all sure we'd really heard it, he'd say, "I see dead people." The Millennium Falcon model, the four foot diameter model used in the first film, had a narration about the winding-up sound effect they used when the hyper drive was malfunctioning, complete with Lando's "YeeeeHawwww" when it finally kicked in. But the lullapalooza, the one that haunts all of us to this day, was the movie clip that ran beside the landspeeder, all day all night. It started out, all day, all night, every time, with Aunt Beru yelling "Luke! Luke!" Chills!

The day before opening there was a reception for the press and whoever they could get for celebrities. George Lucas was coming. The reception was to be at 7:00, so they chased us out at 6:00. "Wow, cool, a short day!" we said. "Wait a minute, that was a twelve hour day!"

Friday, June 17, 2011

Dimensional Shift

I can't believe I forgot this one. Once again, I don't recall exactly when it occurred, but it was in the range of spring 1990 to spring 1994 - it doesn't matter. Image International. 1992? Sure.

It was a waning afternoon, getting close to time to punch out and go home. The phone rang and someone in the Production office answered it. Within seconds he was out the door and headed straight for me! My first impulse was to run. I didn't.

"The guys at the Marriott are in the weeds!" he said. "They need more table cloths and chair condoms."

"That's very interesting," I said. "Thanks for letting me know." Sarcasm was dripping in gobs.

"You have to take the stuff down!" he said.

"ME?"

"You have a driver's license."

"Oh. Yeah." Most of our fine crew had beed busted for DUI at one time or another. So, because I was a good boy and had NOT lost my license, I was gifted with driving duty a lot.

"Some guys are loading the Step Van. Take the stuff down and help them finish up."

"Grrrrrrrumble grrrrrrrumble!"

Many expletives have been deleted for the sake of all the youngsters who read this blog. Suffice it to say that I was livid. Instead of winding up the day in the shop and going home, I was going to the Marriott Orlando World Center to bail out the crew down there. Table cloths! Chair condoms! Damn it, Jim! I'm a carpenter not a caterer! Otto had to show me the correct installation of chair condoms, and I was turned loose to get 'er done before time for the dinner. Grumble grumble grouse chair condoms! Grumble grumble grouse table cloths! Grumble grumble!

Then the band came out to do a sound check.

Marilyn McCoo, Billy Davis Junior and the rest of the Fifth Dimension sang five songs just for us, the table cloth and chair condom installers, as well as the hotel staff putting out place settings and setting up buffet tables. They did Aquarius, Up Up And Away, Wedding Bell Blues, Last Night I Didn't Get To Sleep At All and One Less Bell To Answer.

Sometimes even the worst indignities are worth it. I sang all the way back to the shop and home from there.

It was a waning afternoon, getting close to time to punch out and go home. The phone rang and someone in the Production office answered it. Within seconds he was out the door and headed straight for me! My first impulse was to run. I didn't.

"The guys at the Marriott are in the weeds!" he said. "They need more table cloths and chair condoms."

"That's very interesting," I said. "Thanks for letting me know." Sarcasm was dripping in gobs.

"You have to take the stuff down!" he said.

"ME?"

"You have a driver's license."

"Oh. Yeah." Most of our fine crew had beed busted for DUI at one time or another. So, because I was a good boy and had NOT lost my license, I was gifted with driving duty a lot.

"Some guys are loading the Step Van. Take the stuff down and help them finish up."

"Grrrrrrrumble grrrrrrrumble!"

Many expletives have been deleted for the sake of all the youngsters who read this blog. Suffice it to say that I was livid. Instead of winding up the day in the shop and going home, I was going to the Marriott Orlando World Center to bail out the crew down there. Table cloths! Chair condoms! Damn it, Jim! I'm a carpenter not a caterer! Otto had to show me the correct installation of chair condoms, and I was turned loose to get 'er done before time for the dinner. Grumble grumble grouse chair condoms! Grumble grumble grouse table cloths! Grumble grumble!

Then the band came out to do a sound check.

Marilyn McCoo, Billy Davis Junior and the rest of the Fifth Dimension sang five songs just for us, the table cloth and chair condom installers, as well as the hotel staff putting out place settings and setting up buffet tables. They did Aquarius, Up Up And Away, Wedding Bell Blues, Last Night I Didn't Get To Sleep At All and One Less Bell To Answer.

Sometimes even the worst indignities are worth it. I sang all the way back to the shop and home from there.

Monday, May 9, 2011

Goose Bumps

A year and a half ago I was in Albuquerque, laid up in a recliner with an oxygen tank wishing I could go see "Irving Berlin's White Christmas" to be wowed by the many fluid scene changes. Colby Landers designed the eleven sets and between us we engineered how to make them work. The situation at Albuquerque Little Theatre was a lot better than Meadville Community Theatre in that sets not in use could be rolled out the back of the stage and into the shop. The shop was pretty full of scenery during most of the show. I bought a DVD of the show, but the scene changes didn't give me goosebumps watching the little TV screen.

Wednesday night I watched a rehearsal of act one of "The Secret Garden." The first time the interior of Misselthwaite Manor magically spun to become the Garden, I got goosebumps. That's what I'm in it for, the goosebumps. The actors that turned the rolling double sided pieces did so flawlessly more times than not. By Friday night opening it was even better.

After all these years, I still get a kick out of show biz.

Wednesday night I watched a rehearsal of act one of "The Secret Garden." The first time the interior of Misselthwaite Manor magically spun to become the Garden, I got goosebumps. That's what I'm in it for, the goosebumps. The actors that turned the rolling double sided pieces did so flawlessly more times than not. By Friday night opening it was even better.

After all these years, I still get a kick out of show biz.

Tuesday, April 26, 2011

Fresh Thoughts About MCT

The first theatre I ever worked in was Riverside Theatre in Vero Beach, Florida. It has since been expanded in many directions, but even in the early eighties it was a gem of a theatre. It has a nice big stage - not as big as some, but pretty durn big for a little place like Vero Beach - with wing space and fly space. It had a well-equipped shop, a green room big enough to rehearse in, big dressing rooms and an enclosed light booth with two follow spots. Sound was equally well provided for, with a booth of its own and microphone and speaker inputs and outputs strategically placed around the stage.

The second one made the first one look mighty good. In 1985, the Vero Beach Theatre Guild bought a church building and made it work as a theatre. The stage was about half the size of Riverside, with no wing space and no fly space. Until the spring of '86, the only way in or out of the stage area was a doorway into the audience. BUT - it had a big green room, dressing rooms and a shop. When we put on "Damn Yankees, with seventeen scenes and twenty seven cast members doing costume changes, we busted a hole through the wall stage left, and built a stairway down to the ground, where a big tent served as green room and dressing rooms. Since then, this theatre has also been expanded and improved.

Albuquerque Little Theatre is littler than the Vero Beach Theatre Guild theatre, with very little wing space and no fly space. But it has a nice big shop, a nice green room, dressing rooms and a big rehearsal space upstairs.

So now we come to Meadville Community Theatre. First thing that smacks you is the proscenium, seven feet six inches high. The thrust of stage in front of the proscenium is really all the stage you have to work with. Inside the arch it has zero wing space, zero fly space and no way to make anything onstage disappear unless it can go through a narrow doorway, down three steps to a sharp turn through a narrow hall to either the audience or the next set of stairs down to ground level where one can go outside through the door, or on the stage left side make a sharp left through another narrow doorway and down more steps to the tiny green room / dressing room / storage room. There is no rehearsal space and no shop. Any cutting or building takes place onstage or (if you're lucky enough to be working on a non-rainy / snowy day) outside. Need flats? Take the stairs down from the stage, go up the aisle to the rear of the house, go through the doors to the stairway about ten steps down to ground level, turn right, go through the double doors to a tiny room - once an office - flip through the flats in stock, pull one out, lay it over so it will fit through the office door, through the double doors, up the ten steps, through those doors, down the aisle and up the steps to the stage. Need lumber? Go down the stage left steps, turn left, go down to ground level and outside through the rain and / or snow to the "hole," a small basement entrance that requires you to bend double to enter and stoop over to walk through. Racks and racks of two by, one by and molding await the stout hearted souls who venture in.

Stout hearted souls are the stuff of Meadville Community Theatre. They feel blessed to have this place to call their own. The laundry list of inconveniences I mentioned are to them a badge of honor, for in spite of all of that, the show goes on!

The second one made the first one look mighty good. In 1985, the Vero Beach Theatre Guild bought a church building and made it work as a theatre. The stage was about half the size of Riverside, with no wing space and no fly space. Until the spring of '86, the only way in or out of the stage area was a doorway into the audience. BUT - it had a big green room, dressing rooms and a shop. When we put on "Damn Yankees, with seventeen scenes and twenty seven cast members doing costume changes, we busted a hole through the wall stage left, and built a stairway down to the ground, where a big tent served as green room and dressing rooms. Since then, this theatre has also been expanded and improved.

Albuquerque Little Theatre is littler than the Vero Beach Theatre Guild theatre, with very little wing space and no fly space. But it has a nice big shop, a nice green room, dressing rooms and a big rehearsal space upstairs.

So now we come to Meadville Community Theatre. First thing that smacks you is the proscenium, seven feet six inches high. The thrust of stage in front of the proscenium is really all the stage you have to work with. Inside the arch it has zero wing space, zero fly space and no way to make anything onstage disappear unless it can go through a narrow doorway, down three steps to a sharp turn through a narrow hall to either the audience or the next set of stairs down to ground level where one can go outside through the door, or on the stage left side make a sharp left through another narrow doorway and down more steps to the tiny green room / dressing room / storage room. There is no rehearsal space and no shop. Any cutting or building takes place onstage or (if you're lucky enough to be working on a non-rainy / snowy day) outside. Need flats? Take the stairs down from the stage, go up the aisle to the rear of the house, go through the doors to the stairway about ten steps down to ground level, turn right, go through the double doors to a tiny room - once an office - flip through the flats in stock, pull one out, lay it over so it will fit through the office door, through the double doors, up the ten steps, through those doors, down the aisle and up the steps to the stage. Need lumber? Go down the stage left steps, turn left, go down to ground level and outside through the rain and / or snow to the "hole," a small basement entrance that requires you to bend double to enter and stoop over to walk through. Racks and racks of two by, one by and molding await the stout hearted souls who venture in.

Stout hearted souls are the stuff of Meadville Community Theatre. They feel blessed to have this place to call their own. The laundry list of inconveniences I mentioned are to them a badge of honor, for in spite of all of that, the show goes on!

Sunday, March 27, 2011

A Little Vacation, Mr. Manley?

This is one of those out-of-sequence stories that occur to me out of the blue. As a matter of fact, I was watching America's Funniest Home Videos the other night when they had a series of "Twenty Five Spurts In Fifteen Seconds," or something similar, showing clips of people being squirted in the face or elsewhere. I was suddenly reminded of the time in (I believe) 1992 when Image International had a gig at The Ritz Carlton Hotel on Amelia Island up near the Georgia line. It was a six-day gig from Friday to Wednesday. I was invited to the meeting, because Eddie and I were the shop at the time, and he was being sent out on some other job. This gig began with an outdoor symphony concert, with a 24' X 32' stage to build, and then an arcade to assemble brick walls for. (Ray sold forty brick panels. Al gave him twenty.) Then we had three days off, unpaid, before the big outdoor Games Night and strike on Wednesday night. The rules were read to us about our time at the Ritz - no pool use, no lounging in common areas, dress and act professional at all times while on hotel property - so I said, "If I'm not being paid, I'm going home!" Of course, this raised a ruckus. Kevin Rose said, "Don't you want a little vacation?" I told him I didn't call it a vacation if I'm stuck in a room with two other guys and can't enjoy myself in any way. Well, they weren't driving me home or flying me home, and I wasn't to ride my motorcycle there (heaven forbid!) So I asked for a round trip bus ticket from Jacksonville. That they went for, because nobody else in the crew could do the stage on Friday, or the Velcro wall on Wednesday.

For this party I built one of my most elaborate games, a slanting eight foot tall by four foot wide polygon, 6 inches thick, with holes of various sizes and placements for different point values. The whiffle softballs were tossed at the holes for points, and the internal structure channeled each ball from the hole to the slot at the bottom numbered with the corresponding points. It was very popular.

So on Friday, bright and early, we all piled into various cars and trucks and lit out for Amelia Island. After depositing our luggage in our rooms, booked in the name of crew boss David Manley, we set out for the truck to unload what we needed for the first day, the staging. It was brought out to the edge of the practice putting green, where I was instructed to set it up. I started out using big chunks of lumber to shim up the low places and make it level. But the client came along and told me he wanted the stage to kind of roll with the landscape. So I pulled out most of the shims and screwed together the frames as best I could with the roll of the landscape. The plywood decking was a little challenging to make pretty. I had barely begun plywood when the tent company came and asked for a hole to be cut in the center sheet of plywood for the center tent pole. This I did, then finished the plywood while the tent went up around me.

Saturday morning I awoke to find myself alone. I looked out the sliding glass doors to the green, where David Manley and his crew were almost finished painting the entire stage black. I turned away, but suddenly there was screaming from the green area. I turned back to see the guys scurrying away because the sprinkler system had come on. There were three or four Rainbird sprinklers shooting streams of water at the freshly painted stage. By the time they got the hotel to shut the sprinklers off, the stage was badly in need of another coat of paint.

We then began to load in and set up the brick panels for the arcade. This was in another tent, with a grass floor. We had it pretty much together when the games company arrived with the pinball machines, basketball game, air hockey etc. We were stringing extension cords all over the tent, and had just about finished when the Florida afternoon thunderstorm hit. Within minutes we were standing in two inches of water in the middle of dozens of electrical cords strewn around the floor. Time to go.

I got a ride to the Jacksonville bus station and was home before midnight. The return trip began late Monday night. I would arrive in Jax early early Tuesday morning. I had my suitcase loaded with one change of clothes and my tools. It was pretty heavy. I knew before I got there that what I wanted to do was to walk from downtown Jacksonville to the Island, twenty some miles. I damn near made it, too. At the bridge to the island was a little convenience store/bait shop. I used their phone to call Ray Ramsey. He came and got me. As I exited Ray's car, a hotel employee came and grabbed my suitcase. "I'll get that, Mr. Manley!" I told him a) I was going outside to the green with that suitcase and b) I had no tip money. "It's my pleasure, Mr. Manley!" I imagined that, after years of being taken for granted by the usual rich people, it was something of a treat for these employees to go the extra mile for us working stiffs, tip or no (and the client was paying them a big gratuity for all of the Mr. Manleys on the crew.)

So I did some prep work, stapling "loop" fabric on the plywood for the Velcro wall Tuesday night, and Wednesday morning began assembling three eight foot by twelve foot frames into a slanted twelve foot tall by twenty four wide climbing wall, with enough 2X4s to hold it together and stand it up. This took the major part of the day. Then I stood up my new ball toss game and helped with the rest of the party decor until nightfall, when a guy took my suitcase to my room and said "My pleasure, Mr. Manley!" I sat in the comfy chair and watched the party out the glass doors, dozing in and out until the real Mr. Manley called us out for strike. We had everything disassembled and in the truck before you could say "My pleasure, Mr. Manley!"

For this party I built one of my most elaborate games, a slanting eight foot tall by four foot wide polygon, 6 inches thick, with holes of various sizes and placements for different point values. The whiffle softballs were tossed at the holes for points, and the internal structure channeled each ball from the hole to the slot at the bottom numbered with the corresponding points. It was very popular.

So on Friday, bright and early, we all piled into various cars and trucks and lit out for Amelia Island. After depositing our luggage in our rooms, booked in the name of crew boss David Manley, we set out for the truck to unload what we needed for the first day, the staging. It was brought out to the edge of the practice putting green, where I was instructed to set it up. I started out using big chunks of lumber to shim up the low places and make it level. But the client came along and told me he wanted the stage to kind of roll with the landscape. So I pulled out most of the shims and screwed together the frames as best I could with the roll of the landscape. The plywood decking was a little challenging to make pretty. I had barely begun plywood when the tent company came and asked for a hole to be cut in the center sheet of plywood for the center tent pole. This I did, then finished the plywood while the tent went up around me.

Saturday morning I awoke to find myself alone. I looked out the sliding glass doors to the green, where David Manley and his crew were almost finished painting the entire stage black. I turned away, but suddenly there was screaming from the green area. I turned back to see the guys scurrying away because the sprinkler system had come on. There were three or four Rainbird sprinklers shooting streams of water at the freshly painted stage. By the time they got the hotel to shut the sprinklers off, the stage was badly in need of another coat of paint.

We then began to load in and set up the brick panels for the arcade. This was in another tent, with a grass floor. We had it pretty much together when the games company arrived with the pinball machines, basketball game, air hockey etc. We were stringing extension cords all over the tent, and had just about finished when the Florida afternoon thunderstorm hit. Within minutes we were standing in two inches of water in the middle of dozens of electrical cords strewn around the floor. Time to go.

I got a ride to the Jacksonville bus station and was home before midnight. The return trip began late Monday night. I would arrive in Jax early early Tuesday morning. I had my suitcase loaded with one change of clothes and my tools. It was pretty heavy. I knew before I got there that what I wanted to do was to walk from downtown Jacksonville to the Island, twenty some miles. I damn near made it, too. At the bridge to the island was a little convenience store/bait shop. I used their phone to call Ray Ramsey. He came and got me. As I exited Ray's car, a hotel employee came and grabbed my suitcase. "I'll get that, Mr. Manley!" I told him a) I was going outside to the green with that suitcase and b) I had no tip money. "It's my pleasure, Mr. Manley!" I imagined that, after years of being taken for granted by the usual rich people, it was something of a treat for these employees to go the extra mile for us working stiffs, tip or no (and the client was paying them a big gratuity for all of the Mr. Manleys on the crew.)

So I did some prep work, stapling "loop" fabric on the plywood for the Velcro wall Tuesday night, and Wednesday morning began assembling three eight foot by twelve foot frames into a slanted twelve foot tall by twenty four wide climbing wall, with enough 2X4s to hold it together and stand it up. This took the major part of the day. Then I stood up my new ball toss game and helped with the rest of the party decor until nightfall, when a guy took my suitcase to my room and said "My pleasure, Mr. Manley!" I sat in the comfy chair and watched the party out the glass doors, dozing in and out until the real Mr. Manley called us out for strike. We had everything disassembled and in the truck before you could say "My pleasure, Mr. Manley!"

Saturday, March 19, 2011

When The Pupil Is Ready...

In 1995, working at Presentations South, Inc., the job seemed to be: build a box, laminate it - build another box, laminate it etc. In the footsteps of Og, I proved myself to be really not very good at laminating - to the point where things I'd done went on display in the break room for the amusement of the rest of the guys. Jim Matthews kept telling me to ask the other guys for help and advice, which I did, but it didn't seem to help.

At Central Florida Display I did some laminating, but the sucky quality of my work kind of blended in with the general suckiness of Central Florida Display. At F/X there was a laminating department that got upset if the rest of us took work away from them. This suited me fine. For the next nine years, the fact that I couldn't laminate seemed to matter not at all.

At Mystic, whenever they didn't know what to do with someone, they stuck him in the laminating department. Early in my Mystical career I was thrown kicking and screaming into laminating. Pete was on vacation, so Paul was in charge of the department. I thought about putting on a brave face and just diving in. That sounded like a really bad idea. So I went up to Paul and said, "I'm here to help you with the laminating. The problem is, I've never been any good at it. Would you be willing to teach me?" And he did. He took me under his wing and showed me, step by step, from the most basic preparations through the gluing, the sticking, the rubbing down and the filing. By the end of the first week, my skills had progressed to the point where I could actually fly solo and do an acceptable job at a fairly complex project. This was a very good thing, because the laminating department only did about half of the laminating in the building. The cabinet guys pretty much all did their own, because they all did it so much better than Pete, just ask them. When the scenery division had laminating to do, there was usually a lot of it, and Pete's guys couldn't handle it all and get it done on time. I actually became one of the better laminators in the scenery section. All thanks to Paul, my sensei.

At Central Florida Display I did some laminating, but the sucky quality of my work kind of blended in with the general suckiness of Central Florida Display. At F/X there was a laminating department that got upset if the rest of us took work away from them. This suited me fine. For the next nine years, the fact that I couldn't laminate seemed to matter not at all.

At Mystic, whenever they didn't know what to do with someone, they stuck him in the laminating department. Early in my Mystical career I was thrown kicking and screaming into laminating. Pete was on vacation, so Paul was in charge of the department. I thought about putting on a brave face and just diving in. That sounded like a really bad idea. So I went up to Paul and said, "I'm here to help you with the laminating. The problem is, I've never been any good at it. Would you be willing to teach me?" And he did. He took me under his wing and showed me, step by step, from the most basic preparations through the gluing, the sticking, the rubbing down and the filing. By the end of the first week, my skills had progressed to the point where I could actually fly solo and do an acceptable job at a fairly complex project. This was a very good thing, because the laminating department only did about half of the laminating in the building. The cabinet guys pretty much all did their own, because they all did it so much better than Pete, just ask them. When the scenery division had laminating to do, there was usually a lot of it, and Pete's guys couldn't handle it all and get it done on time. I actually became one of the better laminators in the scenery section. All thanks to Paul, my sensei.

Friday, March 18, 2011

Tooling Up

My first day at Mystic Scenic Studios was surprising in many ways. For one thing, I found out that there were over a hundred employees with whom I'd be working - a lot of names to learn. For another, I was given, along with my employee handbook, a two page list of tools I was expected to own and use on the job. Everywhere I worked in Florida, they provided things like routers, drills, circular saws, jigsaws, belt sanders etc. They didn't want employees bringing in their own power tools and wearing them out on the job.

For the one thing, I was determined to learn everybody's name as quickly as possible. I've always been sketchy about remembering names, but somehow, a little-used part of my brain fired up. I learned all but a few within a couple weeks. I learned most people's names before they learned mine.

For the other, I bought tools with big overtime checks - which came along frequently in those early days. Belt sander first, then 1/2" chuck corded drill, jig saw, big router, laminate trimmer, 1/2" chuck cordless drill, tilt base trimmer, impact driver, orbital sander etc. I was still buying tools during the last weeks in Massachusetts in 2009.

The two owners of the company (until they finally split up in 2007) were Jim and John. One thing that was interesting about learning all those names was realizing that out of a hundred employees, six were Jims and seven were Johns. Those numbers fluctuated over four years, of course. John would hire a John or two, so Jim would have to bring in some Jims to catch up. In the spring of '07, John left and the Jims reigned supreme.

For the one thing, I was determined to learn everybody's name as quickly as possible. I've always been sketchy about remembering names, but somehow, a little-used part of my brain fired up. I learned all but a few within a couple weeks. I learned most people's names before they learned mine.

For the other, I bought tools with big overtime checks - which came along frequently in those early days. Belt sander first, then 1/2" chuck corded drill, jig saw, big router, laminate trimmer, 1/2" chuck cordless drill, tilt base trimmer, impact driver, orbital sander etc. I was still buying tools during the last weeks in Massachusetts in 2009.

The two owners of the company (until they finally split up in 2007) were Jim and John. One thing that was interesting about learning all those names was realizing that out of a hundred employees, six were Jims and seven were Johns. Those numbers fluctuated over four years, of course. John would hire a John or two, so Jim would have to bring in some Jims to catch up. In the spring of '07, John left and the Jims reigned supreme.

Sunday, March 6, 2011

Frantic Searching

As mentioned in my previous posting, my last day at F/X was April 30th. From then until the end of June life was all about packing and moving and unpacking and setting up for a life in Massachusetts.

I went to Dedham to put in an application at Mystic Scenic Studios, a company I'd heard about because they opened a satellite shop in Central Florida for a short run a few years back. I knew they did good stuff, and I'd heard they paid well. But July is not the best time to go job hunting in show business. This was not a productive trip.

I took the MBCR, the Commuter Rail part of the MBTA, and far superior to the rest of it - just ask them - to Dedham, walked many miles in the blistering heat (this was the worst heat wave in Massachusetts memory) and found the address listed on their website. It was an abandoned

building, up for lease, with a sign on the door directing me to 293 Lenox Street in Norwood. I recognized the address of Mystic Millwork, a division of Mystic Scenic Studios. Did this mean that the scenery shop was out of business? And where in Norwood was Lenox Street? I made a mental list of three things I needed asap: a phone, a map and a restroom.

There was an office building very near the train platform. I was walking by the back door, glanced inside and saw a rest room right next to a stack of phone books for Dedham, Westwood and Norwood. Two of my three problems were solved. The phone book had a map section in the front. I found Lenox Street - it ran right along the Commuter Rail tracks. A nearby hotel had pay phones, so I called the number for the Studios, still listed in Dedham. A person answered, and she assured me that the studios were still very much alive. I asked if they were accepting applications. They were. Back to the Commuter Rail platform I went.

Of course, Norwood has two stops. Norwood Depot is on the north end and Norwood Central is a couple miles south. Where was 293 Lenox Street? No telling. Until, that is, I got off the train at Norwood Depot. That fact should tell you that I walked Lenox Street, which dead-ended into buildings and required a lot of extra walking to get there from here, past Norwood Central Station about a quarter mile. I arrived sweaty and exhausted, and the offices were being remodeled so the air conditioning didn't work. The application I turned in was not my best work, so it didn't surprise me that I heard nothing from them. The fact that much of the crew was busy remodeling told me that the dead slows of summer were in full force.

My next try was Local 11, the IATSE Stagehands Union in Boston. This was on a pouring-down-rain kind of day. Using a combination of my growing knowledge of the MBTA, my excellent Rand McNally map and my never-say-die attitude, I braved unmarked streets, unnumbered buildings and a sign on the outside wall written in Chinese characters, and found the office despite their best efforts to throw me off the scent. Once there, they treated me very well, even though Local 11 has never transferred a membership from another local and they weren't about to start with me. They took my information and put me on the overflow list - if a job comes along that requires more people than their membership, they'll call from the overflow list. I was at the bottom of a long list. Then, in say twenty or thirty years, they might make me a member. The business manager counseled me: "You know, if what you want to do is build scenery, you ought to go to work for Mystic Scenic Studios down in Dedham. They're not Union, but they treat their people well. Some of our guys free-lance down there when things are slow." They sent me to a drug testing facility in Government Center, Boston, which is required when you work at the Fleet Center, now known as the TD Banknorth Garden.

Then I tried Local 481 Studio Mechanics in Woburn. They gladly took my information, my application fee, my First Month's Dues and whatever other fees I had to pay up front. They told me I had to cajole two members in good standing into sponsoring me for membership, and then I might be voted in at the September meeting. The Business Agent counseled me: "You know, if what you want to do is build scenery, you ought to go to work for Mystic Scenic Studios down in Dedham. Some of our guys work down there when things are slow."

I went to the August meeting of 481 and talked to a couple of the guys, showed them my portfolio and gave them copies of my resume. They were impressed. They told me I ought to go to work for Mystic Scenic Studios in Dedham - they did when things were slow (which they often were.) When I got home, I emailed my resume to Andrew Shiels, the hiring guy at Mystic. I also sent one to Party By Design, als recommended by the 481 guys.

And I put in an application at The Home Depot in Watertown.

Local 11 called me to do a load out of a Kenny Chesney show at Gillette Stadium in Foxboro. I worked from 10:00pm to about 4:00am and netted about a hundred fifty bucks. That was the last union gig I ever did until last summer in Albuquerque.

The Home Depot called me for an interview. I went in and talked to the manager. He sent me to a drug testing place in Brookline and set me up for an orientation class the following Tuesday, provided the drug test results were in. Well, the test results were not in for any of us scheduled for that class. I went to Watertown and was sent back home. The training was rescheduled for Saturday. I was pretty bummed out.

Then Wednesday, Party By Design called me to come interview, which I did. They were happy with me and thought they could hire me, they'd let me know in a couple of days.

Then Thursday Mystic called me in for an interview. They were happy with me and thought they could hire me, and I should call back on Friday afternoon. Suddenly, on Friday, August 19th, I was faced with telling two of my definite prospects that I was not available.

On Monday, August 22nd, I hauled my tools to Norwood for my first day at Mystic Scenic Studios, a happy union that lasted almost four years.

I went to Dedham to put in an application at Mystic Scenic Studios, a company I'd heard about because they opened a satellite shop in Central Florida for a short run a few years back. I knew they did good stuff, and I'd heard they paid well. But July is not the best time to go job hunting in show business. This was not a productive trip.

I took the MBCR, the Commuter Rail part of the MBTA, and far superior to the rest of it - just ask them - to Dedham, walked many miles in the blistering heat (this was the worst heat wave in Massachusetts memory) and found the address listed on their website. It was an abandoned

building, up for lease, with a sign on the door directing me to 293 Lenox Street in Norwood. I recognized the address of Mystic Millwork, a division of Mystic Scenic Studios. Did this mean that the scenery shop was out of business? And where in Norwood was Lenox Street? I made a mental list of three things I needed asap: a phone, a map and a restroom.

There was an office building very near the train platform. I was walking by the back door, glanced inside and saw a rest room right next to a stack of phone books for Dedham, Westwood and Norwood. Two of my three problems were solved. The phone book had a map section in the front. I found Lenox Street - it ran right along the Commuter Rail tracks. A nearby hotel had pay phones, so I called the number for the Studios, still listed in Dedham. A person answered, and she assured me that the studios were still very much alive. I asked if they were accepting applications. They were. Back to the Commuter Rail platform I went.

Of course, Norwood has two stops. Norwood Depot is on the north end and Norwood Central is a couple miles south. Where was 293 Lenox Street? No telling. Until, that is, I got off the train at Norwood Depot. That fact should tell you that I walked Lenox Street, which dead-ended into buildings and required a lot of extra walking to get there from here, past Norwood Central Station about a quarter mile. I arrived sweaty and exhausted, and the offices were being remodeled so the air conditioning didn't work. The application I turned in was not my best work, so it didn't surprise me that I heard nothing from them. The fact that much of the crew was busy remodeling told me that the dead slows of summer were in full force.

My next try was Local 11, the IATSE Stagehands Union in Boston. This was on a pouring-down-rain kind of day. Using a combination of my growing knowledge of the MBTA, my excellent Rand McNally map and my never-say-die attitude, I braved unmarked streets, unnumbered buildings and a sign on the outside wall written in Chinese characters, and found the office despite their best efforts to throw me off the scent. Once there, they treated me very well, even though Local 11 has never transferred a membership from another local and they weren't about to start with me. They took my information and put me on the overflow list - if a job comes along that requires more people than their membership, they'll call from the overflow list. I was at the bottom of a long list. Then, in say twenty or thirty years, they might make me a member. The business manager counseled me: "You know, if what you want to do is build scenery, you ought to go to work for Mystic Scenic Studios down in Dedham. They're not Union, but they treat their people well. Some of our guys free-lance down there when things are slow." They sent me to a drug testing facility in Government Center, Boston, which is required when you work at the Fleet Center, now known as the TD Banknorth Garden.

Then I tried Local 481 Studio Mechanics in Woburn. They gladly took my information, my application fee, my First Month's Dues and whatever other fees I had to pay up front. They told me I had to cajole two members in good standing into sponsoring me for membership, and then I might be voted in at the September meeting. The Business Agent counseled me: "You know, if what you want to do is build scenery, you ought to go to work for Mystic Scenic Studios down in Dedham. Some of our guys work down there when things are slow."

I went to the August meeting of 481 and talked to a couple of the guys, showed them my portfolio and gave them copies of my resume. They were impressed. They told me I ought to go to work for Mystic Scenic Studios in Dedham - they did when things were slow (which they often were.) When I got home, I emailed my resume to Andrew Shiels, the hiring guy at Mystic. I also sent one to Party By Design, als recommended by the 481 guys.

And I put in an application at The Home Depot in Watertown.

Local 11 called me to do a load out of a Kenny Chesney show at Gillette Stadium in Foxboro. I worked from 10:00pm to about 4:00am and netted about a hundred fifty bucks. That was the last union gig I ever did until last summer in Albuquerque.

The Home Depot called me for an interview. I went in and talked to the manager. He sent me to a drug testing place in Brookline and set me up for an orientation class the following Tuesday, provided the drug test results were in. Well, the test results were not in for any of us scheduled for that class. I went to Watertown and was sent back home. The training was rescheduled for Saturday. I was pretty bummed out.

Then Wednesday, Party By Design called me to come interview, which I did. They were happy with me and thought they could hire me, they'd let me know in a couple of days.

Then Thursday Mystic called me in for an interview. They were happy with me and thought they could hire me, and I should call back on Friday afternoon. Suddenly, on Friday, August 19th, I was faced with telling two of my definite prospects that I was not available.

On Monday, August 22nd, I hauled my tools to Norwood for my first day at Mystic Scenic Studios, a happy union that lasted almost four years.

Monday, February 14, 2011

Cutting The Cord

I know I'll regret posting this whenever random memories surface that could have been included in the F/X portion of my show biz history. Nine and a quarter years is the second longest time I've ever stayed with one company, and the longer one was the family commercial art business. Truth be told, the longest stretch there, March '78 to March '87, was three months shorter - but I digress.

Carmen graduated Leslie University's Intensive Residency program in May of '04 and immediately began getting together her applications to three theological schools: Vanderbilt Divinity in Nashville, Harvard Divinity in Cambridge, MA and Andover Newton Theological School in Newton, MA. I could tell by the vibes that she wanted to go to greater Boston, but would go to Tennessee if that was her only option. It wasn't. It came to pass, as everyone but Carmen knew it would, that she was accepted to all three. She went to an open house weekend at both Harvard and Andover Newton, and her fancy was tickled by ANTS. In those early months of 2005 we got the house in selling shape and began pulling up stakes, one stake at a time.

Everyone at F/X knew what was happening: the timekeeper was moving away. Management began pressing me to declare when I would be leaving. I consulted with my management, and she decided that April 30th would be a good time. F/X hired a new Jim, and I began training the next decks-a-trim installation specialists. As April waned, there was talk of a going away dinner. A dinner? Why do I get a dinner? I've seen hundreds of people leave the fold, and none of them got a dinner. Remembering Red Buttons at the Dean Martin Celebrity Roasts of the seventies, a speech began writing itself in my head. It described many of the great F/X employees who left, and never got a dinner - including Mack's own mother-in-law Peggy, who retired three times and STILL never got a dinner. It was pretty funny, and the large gathering (for a free meal) seemed to enjoy it. The hard part was that the dinner was on the 29th, so I still had one more day to go.

My last day was hard to get through. I don't remember doing anything productive. I cleaned out my box there at the end of my twenty by six foot table. I turned in my company-issued tools and packed up my own tools into my Toyota T100 pickup truck. I pulled out my huge pile of drawings from nine and a quarter years of building scenery exhibits and displays. Anthony Ferguson seemed interested in them, but even more interested in getting a good recording of me shouting "Dot's On The Dot!" before I left. This was very confusing to people who had been conditioned to go on break when they heard that sound.

I was sad to leave, but excited about leaving Florida. I wouldn't need a vehicle in Boston, so I could shed that piece of hardware from my kit! And after twenty-seven years of suffering through summer, we were going to spend at least four years suffering through winter!

Carmen graduated Leslie University's Intensive Residency program in May of '04 and immediately began getting together her applications to three theological schools: Vanderbilt Divinity in Nashville, Harvard Divinity in Cambridge, MA and Andover Newton Theological School in Newton, MA. I could tell by the vibes that she wanted to go to greater Boston, but would go to Tennessee if that was her only option. It wasn't. It came to pass, as everyone but Carmen knew it would, that she was accepted to all three. She went to an open house weekend at both Harvard and Andover Newton, and her fancy was tickled by ANTS. In those early months of 2005 we got the house in selling shape and began pulling up stakes, one stake at a time.

Everyone at F/X knew what was happening: the timekeeper was moving away. Management began pressing me to declare when I would be leaving. I consulted with my management, and she decided that April 30th would be a good time. F/X hired a new Jim, and I began training the next decks-a-trim installation specialists. As April waned, there was talk of a going away dinner. A dinner? Why do I get a dinner? I've seen hundreds of people leave the fold, and none of them got a dinner. Remembering Red Buttons at the Dean Martin Celebrity Roasts of the seventies, a speech began writing itself in my head. It described many of the great F/X employees who left, and never got a dinner - including Mack's own mother-in-law Peggy, who retired three times and STILL never got a dinner. It was pretty funny, and the large gathering (for a free meal) seemed to enjoy it. The hard part was that the dinner was on the 29th, so I still had one more day to go.

My last day was hard to get through. I don't remember doing anything productive. I cleaned out my box there at the end of my twenty by six foot table. I turned in my company-issued tools and packed up my own tools into my Toyota T100 pickup truck. I pulled out my huge pile of drawings from nine and a quarter years of building scenery exhibits and displays. Anthony Ferguson seemed interested in them, but even more interested in getting a good recording of me shouting "Dot's On The Dot!" before I left. This was very confusing to people who had been conditioned to go on break when they heard that sound.

I was sad to leave, but excited about leaving Florida. I wouldn't need a vehicle in Boston, so I could shed that piece of hardware from my kit! And after twenty-seven years of suffering through summer, we were going to spend at least four years suffering through winter!

Saturday, January 29, 2011

Well She's A Brick - Set

The first brick set we did was WAGA, the Fox station in Atlanta. Of course Atlanta thinks of itself as a brick city - Georgia is the red clay capital of the world. So there were brick walls, brick headers, brick columns, brick everywhere. Eddie and I knew how to do brick: go to the lumber yard in Winter Park and buy 4X8 sheets of brick paneling. It looks great with hardly any labor other than cutting chunks to fit while maintaining the integrity of the brick pattern. Other guys knew other ways: buy vacu-formed plastic sheets; make a brick-shaped stamp and dip it in paint between stampings on the wall. No. The New York designers had done a brick wall for MSNBC, shown it to WAGA, and that's what they wanted. Now, try to imagine the most labor-intensive way you can think of to make artificial bricks, and I'll bet the way we were instructed to do it outdoes your idea.

Stage one: cut up 1/2" thick homasote (pressed paper board used for insulation and sound deadening) into brick-sized chunks, which, of course, requires a consensus to be struck about what size a brick-sized chunk should be, which took the better part of a day. Stage two: devise a method by which a brick-sized chunk of homasote can be quickly and fairly consistently split into two brick-sized chunks. This also took the better part of a day. After trying saws, a machete, chisels and any number of knives, the winner was a two inch wide strip of 1/8" aluminum, sharpened on one long edge and wrapped with tape around the end for holding it in place, laid along the center of the edge of each chunk and pounded through with a twenty ounce hammer. So there was also the need for a couple of blocks to hold the brick chunk vertical while its thickness was halved. So, after several days of trial and error and pounding the aluminum blade, we had several boxes of raw material. Stage three: using a series of spacing jigs, the split bricks were contact cemented and stapled to the board, rough side out, with each edge of each wall, header, column coming out to even bricks, which took a little finagling to space correctly. Stage four: the art department took over, first sliming the whole wall, header, column, whatever with joint compound, then when that was dry, he base coated it all brick red, then spattered it all three or four more colors - black, orange, white, yellow whatever - and when that was dry, painted in the mortar lines between each brick. We all just shook our heads in wonderment as the weeks ticked by and slowly this whole process became - I admit it - very realistic rough-brick treatment. Yes, we said, it really looks better than the paneling or the plastic - but when you watch the news, is that what you are seeing? Not if the news is at all interesting. And we knew from Court TV that you almost never see any part of the set anyway.

The bottom line for us is, if someone is happy to pay us to turn a one-day project into a three-week project, we're happy to take their money.

A year or so later, I heard that we were going to do WMAR TV Baltimore. I was bred and bawn in Baltimore, so I had an inkling that the box of leftover bricks were going to finally get used. Even though this set was designed by F/X designers, they opted for the same proven method for the whole WMAR set. Proven, that is, to be the most time-consuming possible way to make fake brick walls short of slicing up real bricks.

Stage one: cut up 1/2" thick homasote (pressed paper board used for insulation and sound deadening) into brick-sized chunks, which, of course, requires a consensus to be struck about what size a brick-sized chunk should be, which took the better part of a day. Stage two: devise a method by which a brick-sized chunk of homasote can be quickly and fairly consistently split into two brick-sized chunks. This also took the better part of a day. After trying saws, a machete, chisels and any number of knives, the winner was a two inch wide strip of 1/8" aluminum, sharpened on one long edge and wrapped with tape around the end for holding it in place, laid along the center of the edge of each chunk and pounded through with a twenty ounce hammer. So there was also the need for a couple of blocks to hold the brick chunk vertical while its thickness was halved. So, after several days of trial and error and pounding the aluminum blade, we had several boxes of raw material. Stage three: using a series of spacing jigs, the split bricks were contact cemented and stapled to the board, rough side out, with each edge of each wall, header, column coming out to even bricks, which took a little finagling to space correctly. Stage four: the art department took over, first sliming the whole wall, header, column, whatever with joint compound, then when that was dry, he base coated it all brick red, then spattered it all three or four more colors - black, orange, white, yellow whatever - and when that was dry, painted in the mortar lines between each brick. We all just shook our heads in wonderment as the weeks ticked by and slowly this whole process became - I admit it - very realistic rough-brick treatment. Yes, we said, it really looks better than the paneling or the plastic - but when you watch the news, is that what you are seeing? Not if the news is at all interesting. And we knew from Court TV that you almost never see any part of the set anyway.

The bottom line for us is, if someone is happy to pay us to turn a one-day project into a three-week project, we're happy to take their money.

A year or so later, I heard that we were going to do WMAR TV Baltimore. I was bred and bawn in Baltimore, so I had an inkling that the box of leftover bricks were going to finally get used. Even though this set was designed by F/X designers, they opted for the same proven method for the whole WMAR set. Proven, that is, to be the most time-consuming possible way to make fake brick walls short of slicing up real bricks.

Monday, January 10, 2011

Inventions

One thing about working in show biz is that there are things to be done that nobody has ever encountered, st least not often enough for the special tool or hardware to be available. Thinking back to Imasge International, I'm remembering an oblong tube of brass that was just wide enough and deep enough to slide over a cup hook, with a short shaft that went into your cordless drill. Each Christmas season, the guys hung decorations all over Disney World and other places using cup hooks - hundreds of them. This invention turned cup hook installation into a seconds long project instead of a minutes long one. I didn't invent that one. I think maybe Eddie did.