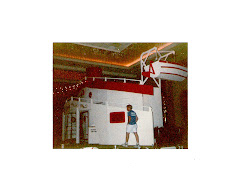

Mere days after the opening of the Star Wars exhibit, we were back in the Museum Of Science early on Saturday morning, October 29th. The "Air Car" ride was malfunctioning. Armed with drills and hammers and implements of destruction, we tore apart the little enclosed track and put it back together with a stronger knee wall around it. The broken plate on the car itself, a swivel thing that allowed steering, was removed so it could be returned to the shop for repair or replacement. A sign was placed at the entrance to the ride: "The Repair Droids are still working on this activity. Please come back later." Six months later, when disassembling and packing the exhibit for its world tour, I happened upon that sign. I still have it.

November, December and January I was often derailed from my Norwood projects for night shift gigs at MOS. Broken things were replaced and newly acquired elements were added that there hadn't been time for before opening. Cabinet doors were added, venting holes and fans were installed, labeling signs were installed on permanent posts, all kinds of little things.

And then we began a systematic measuring of all thirty-some glass cases, complete with drawings of the power inlets and forklifting access panels. Why? Because crates were required for shipping these giant glass boxes. Kevin and I spent several nights taking careful measurements. He wrote down the numbers and drew the locations of whatever needed to be accomodated. We compiled the "bible" of Star Wars crates and then began to assemble sides back at the shop. These were not your usual crates. They were individual sides, with 2X2 around the edges, drilled for bolt assembly. The top was a 1X6, mitred on the ends, that hooked over the top of the case. A huge stack of these sides began piling up in the shop, until Kevin took a bunch to the Museum to begin test-fitting them and modifying whatever slight miscalculations there might have been. For a couple of weeks, I was crate building guru, while Kevin worked nights fitting and tweaking.

May Day! May Day! Monday, May first was the beginning of the strike. I, of course, was put on the strike crew. I hardly did any striking, however. I was put on the finishing up project. There was a long list of trim pieces to add, threaded inserts to install, sign holders to secure for transport, and securing anything loose. Two weeks we spent finishing as many details as possible, packing things up and loading them onto thirteen semi trailers. That's a lot of stuff.

Star Wars has been all over the country and all over the world - Alaska, Europe, Japan, Australia, New Zealand, and on and on. Shawn Marler and Vinnie Canney have been the point men from Mystic taking turns unloading, unpacking and setting up - and striking, packing and loading. I suppose that, five years later, it's still on tour. I hope it's finally finished by now.

Sunday, July 10, 2011

Friday, July 1, 2011

Luke!....Luke!

Years ago, and I'm talking decades ago - say, 1988 or '89 - I was in the Orlando Science Center when a big section was walled off. Througfh cracks in the temporary walls I could see crews working, installing exhibits. "Wow!" I said. "I could do that job!"

Flow downstream to 2004. We were in Boston for Carmen's thesis presentation in April, and her graduation from Lesley University in May. It seemed like every place we went we went within view of the Museum of Science. I gazed hungrily at it. I wanted to go there.

Another year and four months passes, and I'm called into the office, issued my first "Mystic Scenic Studios" T-shirt and told to show up with my tools the next morning at 7:00 at the Museum of Science to work for a few days. Double you oh double you.

The next morning was my first experience with the MBTA's "bus replacement" service. One of the effects of the Big Dig was that it interrupted service on the Green Line west of North Station - where Science Park station is located - so there was "bus replacement" service to get people there. Knowing what I know now, I would have skipped the Green Line altogether, but I didn't. Since my intention was to get there forty five minutes early, even with the hellacious cluster fuckage that is MBTA "bus replacement" service, I was fifteen minutes early. Which means I beat Kevin Simard, the Mystic crew boss, by about forty five minutes.

From information gleaned then and since, I believe I understand the situation. First of all, the Museum Of Science (MOS) contract was administered by Allan McNab, not Jim Ray or Jon Hondorp, which means that Kevin got for his crew whoever those two company owners were willing to let go. The dregs, for the most part. So Kevin and the dregs had been in there for quite a while building walls and rooms and other assorted structures for the new "Weather" exhibit in the big room where the World's Largest Air Insulated Vandegraff Generator works its lightning magic two shows a day. They needed expert help to finish up. Most of the really good carpenters at Mystic live south, in or near Norwood and Dedham. They hate to drive into the city. I, on the other hand, lived in Belmont, and the MOS was closer for me by far.

They needed to finish up because pieces of the brand new Star Wars exhibit were on trucks rolling out of Norwood a couple times a week. This meant stopping work on the Weather stuff, cleaning up and securing everything, going out to the parking garage, unloading a huge chunk of the Millennium Falcon, rolling it on dollies to the storage room, and then going back to work on Weather.

I didn't much like Kevin. He was a crack head, a smart-ass and a practical joker, but he had a long-standing rapport with the Museum people. He had been the Mystic Man there for eight years, and knew every inch of the building and every quirk of the Exhibits Department personnel. I loved working at the Museum, even if it meant working with Kevin. Kevin liked me because a) I could get things done and done right, and b) I have no authority issues. He told me what to do and I said "Yes sir!" and did it.

Too soon I was called back to Norwood for some Jim Ray job or Jon Hondorp job that needed all competent hands.

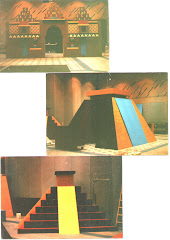

The next time I went back to MOS was for the Star Wars Exhibit installation. This was either at the end of September or the beginning of October. It turned out that what Mystic was sending to be installed wasn't anywhere near finished. All of the big glass cases were a base, a back board, a ceiling and three or four or five or six sheets of tempered glass, half an inch thick. Oh yes, and many cases of clear adhesive caulk. A base was positioned and leveled, a ladder was placed on it, and the back board was glued and screwed to the base. Caulk was squeezed into the groove near the edge, and a sheet of glass, maybe three feet wide by seven feet tall, was dropped into the groove. A person sat on the ladder and held the glass while caulk was squeezed for the next sheet of glass, and the next. The last sheet of glass was the door, no caulk allowed. Then the ceiling piece had its grooves caulked, except for the side where the door was, and it was hoisted up to guys on ladders who handed it over to the inside person, and it was eased down, glass being teased into grooves and the back board screwed into place. The door was removed so that the inside person could escape the caulk fumes and the precision caulking crew could connect the corners and other seams while the base levelers moved on to the next case.

There were about thirty TV panels, where a monitor was fitted into a pre-cut rectangular hole, a graphic panel was fitted over it, and holes needed to be drilled for control buttons for "UP" "SELECT" and "DOWN." This was my introduction to drilling one inch holes through quarter inch plexiglass with a paddle bit. Before Kevin showed me how, I would have sworn that it couldn't work. It works! So job one was to figure out which TV panel you had going, and match it up with its corresponding graphic mounted on the back of oversized quarter inch plexiglass, place it exactly where the monitor was masked perfectly by the opening in the graphic, and mark the graphic exactly where it needed to be cut. Out in the outer room where the gift shop would be, there was a work table set up. You placed your quarter inch plexiglass with the graphic mounted on it, set a straight edge along the cut marks, and ran your router along the straight edge. Then you took your resized graphic panel back to the TV panel, clamped it in place, and began drilling holes for screws and 'finish washers' around the perimeter. Once the graphic was attached, you marked your control button locations and began to slowly drill your one inch holes through the plexi, through the graphic and through the board of the TV panel. Then clean up the mess, install the buttons and move on. About ten of the thirty were instances in which the graphic didn't match the location of the monitor via miscommunication between the designer, Allan McNab, the carpenter(s) or the graphics company. Usually it meant ordering a corrected graphic panel (about $700 each) but a couple of times I was modifying monitor openings to accomodate the graphic. This all took many days. Between the TV panels and all the other exhibits that required control buttons, I estimate that I drilled about five hundred of those one inch holes through plexiglass. It was noisy, too. Throughout the gallery people were complaining about the "screeeyaareeyaareeyaa" noise my paddle bit made, hole after hole, for days on end.

Sixteen hour days were the norm for about two weeks, starting at 6:00am and working until 10:00pm. More and more heavyweight carpenters arrived as opening day drew closer. We started having an overnight shift in addition to the day shift. Tireder and tireder we got. One memorable night at about 7:30, Allan McNab took me over to a panel with about sixteen posts sticking up. He showed me the graphic that was supposed to fit over the panel, with the posts sticking up through it. My job, in my exhausted state, was to drill holes in the plexiglass

graphic so that the posts would stick up through it. I unscrewed posts while Allan looked for a big enough (16" X 30"?) sheet of paper to do a rubbing. I checked the graphic to see if it was the exact right size, and it was. I taped the paper over the panel and rubbed with a pencil over the sixteen or so holes. Then I taped the paper to the plexiglass and, using a plexi drill bit, drilled my holes. Only one gave me trouble, because the post screwed into the unit at a slight, maybe 5 degree angle, so the hole needed to be enlarged and angled correctly. When all was said and done, if you went looking for imperfections, you could see that slightly skewed hole. Otherwise, you'd never notice it. It looked good, and no one was more surprised than I.

One by one the looping narrations were turned on and allowed to run all day and all night, to test their durability. There was a face recognition exhibit that had a forlorn voice that periodically called out for someone to come over for a face recognition lesson. Every three minutes or so, he'd say something like "Hey there, come on over." Three minutes later, "I see you." There were probably seven or eight phrases that would suddenly break the silence while we were working. And maybe once an hour, and when we heard it we weren't at all sure we'd really heard it, he'd say, "I see dead people." The Millennium Falcon model, the four foot diameter model used in the first film, had a narration about the winding-up sound effect they used when the hyper drive was malfunctioning, complete with Lando's "YeeeeHawwww" when it finally kicked in. But the lullapalooza, the one that haunts all of us to this day, was the movie clip that ran beside the landspeeder, all day all night. It started out, all day, all night, every time, with Aunt Beru yelling "Luke! Luke!" Chills!

The day before opening there was a reception for the press and whoever they could get for celebrities. George Lucas was coming. The reception was to be at 7:00, so they chased us out at 6:00. "Wow, cool, a short day!" we said. "Wait a minute, that was a twelve hour day!"

Flow downstream to 2004. We were in Boston for Carmen's thesis presentation in April, and her graduation from Lesley University in May. It seemed like every place we went we went within view of the Museum of Science. I gazed hungrily at it. I wanted to go there.

Another year and four months passes, and I'm called into the office, issued my first "Mystic Scenic Studios" T-shirt and told to show up with my tools the next morning at 7:00 at the Museum of Science to work for a few days. Double you oh double you.

The next morning was my first experience with the MBTA's "bus replacement" service. One of the effects of the Big Dig was that it interrupted service on the Green Line west of North Station - where Science Park station is located - so there was "bus replacement" service to get people there. Knowing what I know now, I would have skipped the Green Line altogether, but I didn't. Since my intention was to get there forty five minutes early, even with the hellacious cluster fuckage that is MBTA "bus replacement" service, I was fifteen minutes early. Which means I beat Kevin Simard, the Mystic crew boss, by about forty five minutes.

From information gleaned then and since, I believe I understand the situation. First of all, the Museum Of Science (MOS) contract was administered by Allan McNab, not Jim Ray or Jon Hondorp, which means that Kevin got for his crew whoever those two company owners were willing to let go. The dregs, for the most part. So Kevin and the dregs had been in there for quite a while building walls and rooms and other assorted structures for the new "Weather" exhibit in the big room where the World's Largest Air Insulated Vandegraff Generator works its lightning magic two shows a day. They needed expert help to finish up. Most of the really good carpenters at Mystic live south, in or near Norwood and Dedham. They hate to drive into the city. I, on the other hand, lived in Belmont, and the MOS was closer for me by far.

They needed to finish up because pieces of the brand new Star Wars exhibit were on trucks rolling out of Norwood a couple times a week. This meant stopping work on the Weather stuff, cleaning up and securing everything, going out to the parking garage, unloading a huge chunk of the Millennium Falcon, rolling it on dollies to the storage room, and then going back to work on Weather.

I didn't much like Kevin. He was a crack head, a smart-ass and a practical joker, but he had a long-standing rapport with the Museum people. He had been the Mystic Man there for eight years, and knew every inch of the building and every quirk of the Exhibits Department personnel. I loved working at the Museum, even if it meant working with Kevin. Kevin liked me because a) I could get things done and done right, and b) I have no authority issues. He told me what to do and I said "Yes sir!" and did it.

Too soon I was called back to Norwood for some Jim Ray job or Jon Hondorp job that needed all competent hands.

The next time I went back to MOS was for the Star Wars Exhibit installation. This was either at the end of September or the beginning of October. It turned out that what Mystic was sending to be installed wasn't anywhere near finished. All of the big glass cases were a base, a back board, a ceiling and three or four or five or six sheets of tempered glass, half an inch thick. Oh yes, and many cases of clear adhesive caulk. A base was positioned and leveled, a ladder was placed on it, and the back board was glued and screwed to the base. Caulk was squeezed into the groove near the edge, and a sheet of glass, maybe three feet wide by seven feet tall, was dropped into the groove. A person sat on the ladder and held the glass while caulk was squeezed for the next sheet of glass, and the next. The last sheet of glass was the door, no caulk allowed. Then the ceiling piece had its grooves caulked, except for the side where the door was, and it was hoisted up to guys on ladders who handed it over to the inside person, and it was eased down, glass being teased into grooves and the back board screwed into place. The door was removed so that the inside person could escape the caulk fumes and the precision caulking crew could connect the corners and other seams while the base levelers moved on to the next case.

There were about thirty TV panels, where a monitor was fitted into a pre-cut rectangular hole, a graphic panel was fitted over it, and holes needed to be drilled for control buttons for "UP" "SELECT" and "DOWN." This was my introduction to drilling one inch holes through quarter inch plexiglass with a paddle bit. Before Kevin showed me how, I would have sworn that it couldn't work. It works! So job one was to figure out which TV panel you had going, and match it up with its corresponding graphic mounted on the back of oversized quarter inch plexiglass, place it exactly where the monitor was masked perfectly by the opening in the graphic, and mark the graphic exactly where it needed to be cut. Out in the outer room where the gift shop would be, there was a work table set up. You placed your quarter inch plexiglass with the graphic mounted on it, set a straight edge along the cut marks, and ran your router along the straight edge. Then you took your resized graphic panel back to the TV panel, clamped it in place, and began drilling holes for screws and 'finish washers' around the perimeter. Once the graphic was attached, you marked your control button locations and began to slowly drill your one inch holes through the plexi, through the graphic and through the board of the TV panel. Then clean up the mess, install the buttons and move on. About ten of the thirty were instances in which the graphic didn't match the location of the monitor via miscommunication between the designer, Allan McNab, the carpenter(s) or the graphics company. Usually it meant ordering a corrected graphic panel (about $700 each) but a couple of times I was modifying monitor openings to accomodate the graphic. This all took many days. Between the TV panels and all the other exhibits that required control buttons, I estimate that I drilled about five hundred of those one inch holes through plexiglass. It was noisy, too. Throughout the gallery people were complaining about the "screeeyaareeyaareeyaa" noise my paddle bit made, hole after hole, for days on end.

Sixteen hour days were the norm for about two weeks, starting at 6:00am and working until 10:00pm. More and more heavyweight carpenters arrived as opening day drew closer. We started having an overnight shift in addition to the day shift. Tireder and tireder we got. One memorable night at about 7:30, Allan McNab took me over to a panel with about sixteen posts sticking up. He showed me the graphic that was supposed to fit over the panel, with the posts sticking up through it. My job, in my exhausted state, was to drill holes in the plexiglass

graphic so that the posts would stick up through it. I unscrewed posts while Allan looked for a big enough (16" X 30"?) sheet of paper to do a rubbing. I checked the graphic to see if it was the exact right size, and it was. I taped the paper over the panel and rubbed with a pencil over the sixteen or so holes. Then I taped the paper to the plexiglass and, using a plexi drill bit, drilled my holes. Only one gave me trouble, because the post screwed into the unit at a slight, maybe 5 degree angle, so the hole needed to be enlarged and angled correctly. When all was said and done, if you went looking for imperfections, you could see that slightly skewed hole. Otherwise, you'd never notice it. It looked good, and no one was more surprised than I.

One by one the looping narrations were turned on and allowed to run all day and all night, to test their durability. There was a face recognition exhibit that had a forlorn voice that periodically called out for someone to come over for a face recognition lesson. Every three minutes or so, he'd say something like "Hey there, come on over." Three minutes later, "I see you." There were probably seven or eight phrases that would suddenly break the silence while we were working. And maybe once an hour, and when we heard it we weren't at all sure we'd really heard it, he'd say, "I see dead people." The Millennium Falcon model, the four foot diameter model used in the first film, had a narration about the winding-up sound effect they used when the hyper drive was malfunctioning, complete with Lando's "YeeeeHawwww" when it finally kicked in. But the lullapalooza, the one that haunts all of us to this day, was the movie clip that ran beside the landspeeder, all day all night. It started out, all day, all night, every time, with Aunt Beru yelling "Luke! Luke!" Chills!

The day before opening there was a reception for the press and whoever they could get for celebrities. George Lucas was coming. The reception was to be at 7:00, so they chased us out at 6:00. "Wow, cool, a short day!" we said. "Wait a minute, that was a twelve hour day!"

Subscribe to:

Comments (Atom)